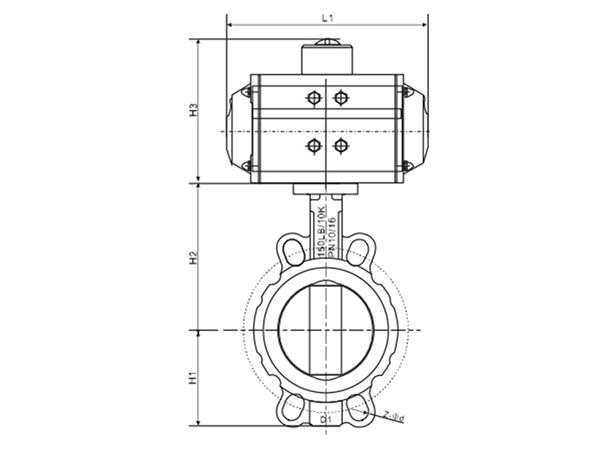

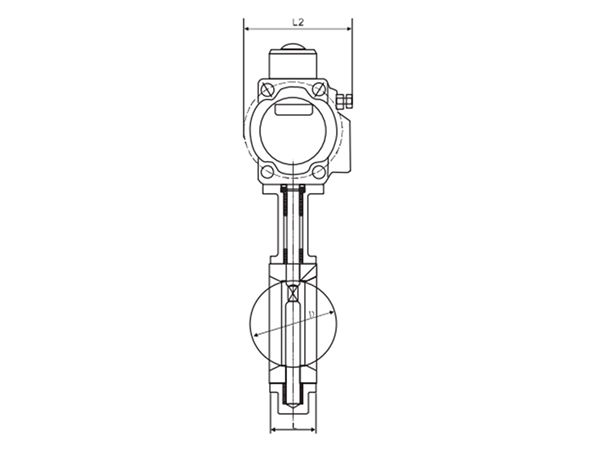

Dimensions (unit: mm)

| DN (mm) | L | L1 | L2 | | PN1.0 | PN1.6 | 150Lb | 10K | D3 | H1 | H2 | H3 |

| D1 | Z- Ød | D1 | Z- Ød | D1 | Z- Ød | D1 | Z- Ød | Flange No. |

| 50 | 42 | 184 | 83 | 52.9 | 125 | 4-19 | 125 | 4-23 | 120.6 | 4-19 | 120 | 4-19 | F05 | 73 | 125 | 120 |

| 65 | 44.7 | 184 | 83 | 64.5 | 145 | 4-19 | 145 | 4-23 | 139.7 | 4-19 | 140 | 4-19 | F05 | 82 | 136 | 120 |

| 80 | 45.2 | 184 | 83 | 78.8 | 160 | 8-19 | 160 | 8-20 | 152.4 | 4-19 | 150 | 8-19 | F05 | 91 | 142 | 120 |

| 100 | 52.1 | 204 | 103 | 104 | 180 | 8-19 | 180 | 4-23 | 190.5 | 8-19 | 175 | 8-19 | F07 | 104 | 163 | 129 |

| 125 | 54.4 | 204 | 103 | 123.3 | 210 | 8-19 | 210 | 4-23 | 215.9 | 8-22 | 210 | 8-23 | F07 | 127 | 176 | 129 |

| 150 | 55.8 | 244 | 103 | 155.6 | 240 | 8-23 | 240 | 4-25 | 241.3 | 8-22 | 240 | 8-23 | F07 | 138 | 197 | 129 |

| 200 | 60.6 | 268 | 122 | 202.5 | 295 | 8-23 | 295 | 4-25 | 298.5 | 8-22 | 290 | 12-23 | F10 | 170 | 230 | 153 |

| 250 | 65.6 | 268 | 122 | 250.5 | 350 | 12-23 | 355 | 4-28 | 362 | 12-25 | 355 | 12-25 | F10 | 204 | 261 | 153 |

| 300 | 77 | 301 | 143 | 301.6 | 400 | 12-23 | 410 | 4-28 | 432 | 12-25 | 400 | 16-25 | F10/12 | 241 | 294 | 175 |

| 350 | 76.5 | 301 | 143 | 333.3 | 460 | 16-23 | 470 | 4-30 | 476 | 12-29 | 445 | 16-25 | F10/12 | 263 | 335 | 175 |

| 400 | 86.5 | 525 | 206 | 389.6 | 515 | 16-28 | 525 | 4-30 | 540 | 16-29 | 510 | 16-27 | F14/16 | 309 | 400 | 260 |

| 450 | 105.6 | 525 | 206 | 440.5 | 565 | 20-28 | 585 | 4-30 | 578 | 16-32 | 565 | 20-27 | F14/16 | 328 | 420 | 260 |

| 500 | 132 | 532 | 226 | 491.6 | 620 | 20-28 | 650 | 4-33 | 635 | 20-32 | 620 | 20-27 | F14/16 | 361 | 480 | 285 |

| 600 | 152 | 602 | 260 | 592.5 | 725 | 20-31 | 770 | 4-36 | 749.5 | 20-35 | 730 | 24-32 | F16 | 459 | 560 | 319 |

| 700 | 163 | | | 695 | 840 | 24-31 | 840 | 24-36 | 864 | 28-35 | 840 | 24-33 | F25 | 520 | 624 | |

| 800 | 188 | | | 794.7 | 950 | 24-34 | 950 | 24-39 | 978 | 28-41 | 950 | 28-33 | F25 | 590 | 680 | |

| 900 | 203 | | | 864.7 | 1050 | 28-34 | 1050 | 28-39 | 1086 | 32-41 | 1050 | 28-33 | F25 | 656 | 720 | |

| 1000 | 216 | | | 965 | 1160 | 28-37 | 1170 | 28-42 | 1200 | 36-41 | 1160 | 28-39 | F25 | 720 | 800 | |

| 1200 | 276 | | | 1158 | 1380 | 32-40 | 1390 | 28-49 | 1422 | 44-41 | 1380 | 32-39 | F30 | 844 | 941 | |

Note: If you need other sizes and materials of butterfly valves, please

contact us

.

The pneumatic actuated butterfly valve is highly useful for controlling highly flammable liquids such as petrochemical products, oil, and natural gas. It works through pneumatic mechanisms, enabling rapid functionality while remaining immune to fire and electrical short circuits. As a result, it is considered the most cost-effective and energy-efficient industrial valve.

We provide switching mode two-position types and intelligent regulating types. If you want to get more information, please

contact us

!

Yes, butterfly sanitary valve can be used in the food processing industry!

Sanitary butterfly valve, also called a hygienic butterfly valve, is a type of flow control device. It is a type of butterfly valve, with the valve body, disc, and other components made of stainless steel.

From 2003 to now, we have more than twenty years of production experience.

As a professional stainless steel casting foundry, we offer precision investment casting, sand casting, and machining services for various industry sectors, in addition to the field of flow control valves.