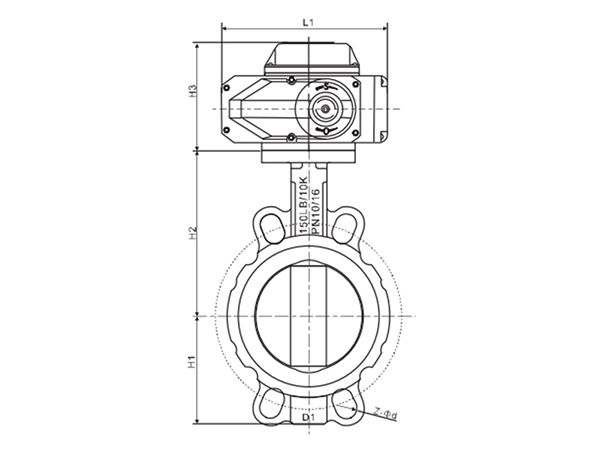

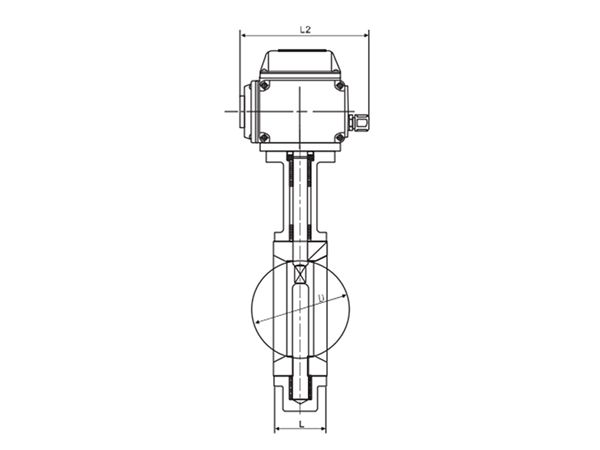

Dimensions (unit: mm)

| DN (mm) | L | L1 | L2 | D | PN1.0 | PN1.6 | 150Lb | 10K | D3 | H1 | H2 | H3 |

| D1 | Z-Ød | D1 | Z- Ød | D1 | Z- Ød | D1 | Z- Ød | Flange No. |

| 50 | 42 | 164 | 136 | 52.9 | 125 | 4-19 | 125 | 4-23 | 120.6 | 4-19 | 120 | 4-19 | F05 | 73 | 125 | 180 |

| 65 | 44.7 | 164 | 136 | 64.5 | 145 | 4-19 | 145 | 4-23 | 139.7 | 4-19 | 140 | 4-19 | F05 | 82 | 136 | 180 |

| 80 | 45.2 | 164 | 136 | 78.8 | 160 | 8-19 | 160 | 8-20 | 152.4 | 4-19 | 150 | 8-19 | F05 | 91 | 142 | 180 |

| 100 | 52.1 | 210 | 156 | 104 | 180 | 8-19 | 180 | 4-23 | 190.5 | 8-19 | 175 | 8-19 | F07 | 104 | 163 | 190 |

| 125 | 54.4 | 210 | 156 | 123.3 | 210 | 8-19 | 210 | 4-23 | 215.9 | 8-22 | 210 | 8-23 | F07 | 127 | 176 | 190 |

| 150 | 55.8 | 210 | 156 | 155.6 | 240 | 8-23 | 240 | 4-25 | 241.3 | 8-22 | 240 | 8-23 | F07 | 138 | 197 | 190 |

| 200 | 60.6 | 256 | 179 | 202.5 | 295 | 8-23 | 295 | 4-25 | 298.5 | 8-22 | 290 | 12-23 | F10 | 170 | 230 | 210 |

| 250 | 65.6 | 256 | 179 | 250.5 | 350 | 12-23 | 355 | 4-28 | 362 | 12-25 | 355 | 12-25 | F10 | 204 | 261 | 210 |

| 300 | 77 | 256 | 179 | 301.6 | 400 | 12-23 | 410 | 4-28 | 432 | 12-25 | 400 | 16-25 | F10/12 | 241 | 294 | 210 |

| 350 | 76.5 | 256 | 179 | 333.3 | 460 | 16-23 | 470 | 4-30 | 476 | 12-29 | 445 | 16-25 | F10/12 | 263 | 335 | 210 |

| 400 | 86.5 | 280 | 179 | 389.6 | 515 | 16-28 | 525 | 4-30 | 540 | 16-29 | 510 | 16-27 | F14/16 | 309 | 400 | 290 |

| 450 | 105.6 | 280 | 179 | 440.5 | 565 | 20-28 | 585 | 4-30 | 578 | 16-32 | 565 | 20-27 | F14/16 | 328 | 420 | 290 |

| 500 | 132 | 280 | 179 | 491.6 | 620 | 20-28 | 650 | 4-33 | 635 | 20-32 | 620 | 20-27 | F14/16 | 361 | 480 | 290 |

| 600 | 152 | 280 | 179 | 592.5 | 725 | 20-31 | 770 | 4-36 | 749.5 | 20-35 | 730 | 24-32 | F16 | 459 | 560 | 290 |

| 700 | 163 | | | 695 | 840 | 24-31 | 840 | 24-36 | 864 | 28-35 | 840 | 24-33 | F25 | 520 | 624 | |

| 800 | 188 | | | 794.7 | 950 | 24-34 | 950 | 24-39 | 978 | 28-41 | 950 | 28-33 | F25 | 590 | 680 | |

| 900 | 203 | | | 864.7 | 1050 | 28-34 | 1050 | 28-39 | 1086 | 32-41 | 1050 | 28-33 | F25 | 656 | 720 | |

| 1000 | 216 | | | 965 | 1160 | 28-37 | 1170 | 28-42 | 1200 | 36-41 | 1160 | 28-39 | F25 | 720 | 800 | |

| 1200 | 276 | | | 1158 | 1380 | 32-40 | 1390 | 28-49 | 1422 | 44-41 | 1380 | 32-39 | F30 | 844 | 941 | |

Note: If you need other sizes and materials of butterfly valves, please

contact us

.

The electric butterfly valve consists of an electric actuator and a butterfly valve, with the advantages of convenient operation and a simple structure common to sanitary butterfly valves. It can also be widely used in industries such as chemicals and pharmaceuticals.

Our electric actuated butterfly valves mainly include flanged butterfly valves and wafer type butterfly valves according to the connection method.

The sealing forms mainly include soft seat valves and hard seat valves. Depending on different functional requirements, they can be categorized as switch-type electric actuated butterfly valves and intelligent regulation-type electric actuated butterfly valves.

Our company is a professional stainless steel precision casting foundry that has a large stock of general valves, and we also provide a variety of customized products according to the purchaser's drawings and materials.

From 2003 to now, we have more than twenty years of production experience.

As a professional stainless steel casting foundry, we offer precision investment casting, sand casting, and machining services for various industry sectors, in addition to the field of flow control valves.