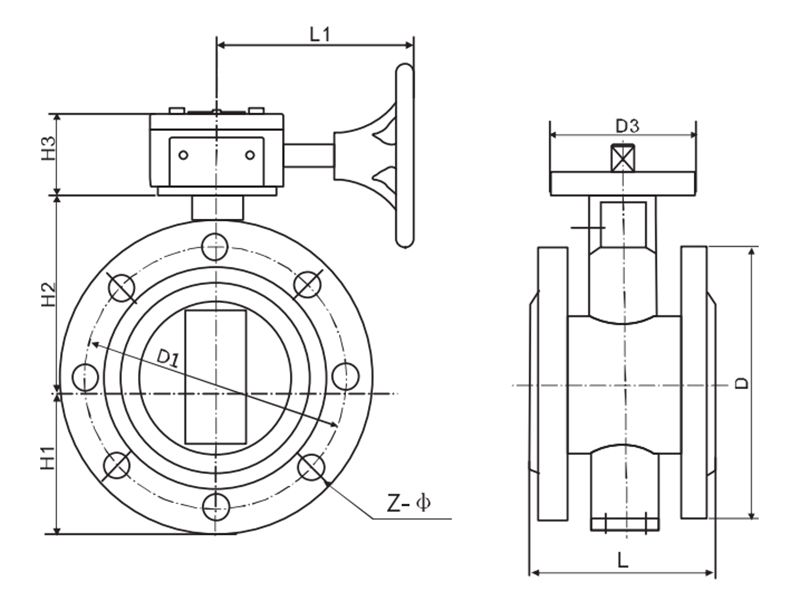

Dimensions (unit: mm)

| DN (mm) | L | L1 | PN1.0 | PN1.6 | 150Lb | 10K | D3 | H1 | H2 | H3 |

| D | D1 | Z-Ød | D | D1 | Z- Ød | D | D1 | Z- Ød | D | D1 | Z- Ød | Flange No. |

| 50 | 108 | 160 | 165 | 125 | 4-19 | 165 | 125 | 4-23 | 150 | 120.6 | 4-19 | 155 | 120 | 4-19 | F05 | 73 | 125 | 60 |

| 65 | 112 | 160 | 185 | 145 | 4-19 | 185 | 145 | 4-23 | 180 | 139.7 | 4-19 | 175 | 140 | 4-19 | F05 | 82 | 136 | 60 |

| 80 | 114 | 160 | 200 | 160 | 8-19 | 200 | 160 | 8-20 | 190 | 152.4 | 4-19 | 185 | 150 | 8-19 | F05 | 91 | 142 | 60 |

| 100 | 127 | 160 | 220 | 180 | 8-19 | 220 | 180 | 4-23 | 230 | 190.5 | 8-19 | 210 | 175 | 8-19 | F07 | 104 | 163 | 60 |

| 125 | 140 | 160 | 250 | 210 | 8-19 | 250 | 210 | 4-23 | 255 | 215.9 | 8-22 | 250 | 210 | 8-23 | F07 | 127 | 176 | 60 |

| 150 | 140 | 160 | 285 | 240 | 8-23 | 285 | 240 | 4-25 | 280 | 241.3 | 8-22 | 280 | 240 | 8-23 | F07 | 138 | 197 | 60 |

| 200 | 152 | 210 | 340 | 295 | 8-23 | 340 | 295 | 4-25 | 345 | 298.5 | 8-22 | 330 | 290 | 12-23 | F10 | 170 | 230 | 72 |

| 250 | 165 | 210 | 395 | 350 | 12-23 | 405 | 355 | 4-28 | 405 | 362 | 12-25 | 400 | 355 | 12-25 | F10 | 204 | 261 | 72 |

| 300 | 178 | 210 | 445 | 400 | 12-23 | 460 | 410 | 4-28 | 485 | 432 | 12-25 | 445 | 400 | 16-25 | F10/12 | 241 | 294 | 75 |

| 350 | 190 | 210 | 505 | 460 | 16-23 | 520 | 470 | 4-30 | 535 | 476 | 12-29 | 490 | 445 | 16-25 | F10/12 | 263 | 335 | 75 |

| 400 | 216 | 320 | 565 | 515 | 16-28 | 580 | 525 | 4-30 | 600 | 540 | 16-29 | 560 | 510 | 16-27 | F14/16 | 309 | 400 | 126 |

| 450 | 222 | 320 | 615 | 565 | 20-28 | 640 | 585 | 4-30 | 635 | 578 | 16-32 | 620 | 565 | 20-27 | F14/16 | 328 | 420 | 126 |

| 500 | 229 | 320 | 670 | 620 | 20-28 | 715 | 650 | 4-33 | 700 | 635 | 20-32 | 675 | 620 | 20-27 | F14/16 | 361 | 480 | 126 |

| 600 | 267 | 340 | 780 | 725 | 20-31 | 840 | 770 | 4-36 | 815 | 749.5 | 20-35 | 795 | 730 | 24-32 | F16 | 459 | 560 | 127 |

| 700 | 292 | 380 | 895 | 840 | 24-31 | 910 | 840 | 24-36 | - | 864 | 28-35 | 905 | 840 | 24-33 | F25 | 520 | 624 | 167 |

| 800 | 318 | 380 | 1015 | 950 | 24-34 | 1025 | 950 | 24-39 | - | 978 | 28-41 | 1020 | 950 | 28-33 | F25 | 590 | 680 | 167 |

| 900 | 330 | 400 | 1115 | 1050 | 28-34 | 1125 | 1050 | 28-39 | - | 1086 | 32-41 | 1120 | 1050 | 28-33 | F25 | 656 | 720 | 193 |

| 1000 | 410 | 400 | 1230 | 1160 | 28-37 | 1255 | 1170 | 28-42 | - | 1200 | 36-41 | 1235 | 1160 | 28-39 | F25 | 720 | 800 | 193 |

| 1200 | 470 | 450 | 1455 | 1380 | 32-40 | 1485 | 1390 | 28-49 | - | 1422 | 44-41 | 1465 | 1380 | 32-39 | F30 | 844 | 941 | |

Note: If you need other sizes and materials of butterfly valves, please

contact us

.

The butterfly valve is used in limited space as well as the fully open and fully closed positions for throttling or regulating flow.

Flanged butterfly valve is a user-friendly switch valve, installed in limited space for adjusting and throttling fluid flow.

Double flange butterfly valve is used for flow regulation and flow segmentation in water utilities, pipelines, irrigation and other areas. Due to the hydrodynamic design of the valve disc, it has a low water head loss, is 100% watertight and is gaskets-free.

Single flange valve is suitable for smaller pipework systems and general industrial applications, typically used in low pressure environments. Double flange valve is suitable for larger pipework systems and high pressure applications, better enduring the high pressure environments.

Butterfly valve, also known as flap valve, can be used to regulate, isolate and control fluid flow.

We produce flow control valves and accessories in accordance with various standards such as GB, ASTM, ASNI, BS, DIN, JIS, etc.!

80% of our industrial valves are exported to the United States, Japan, South Korea, the United Kingdom, Canada, Australia, etc.

As a professional stainless steel casting foundry, we offer precision investment casting, sand casting, and machining services for various industry sectors, in addition to the field of flow control valves.