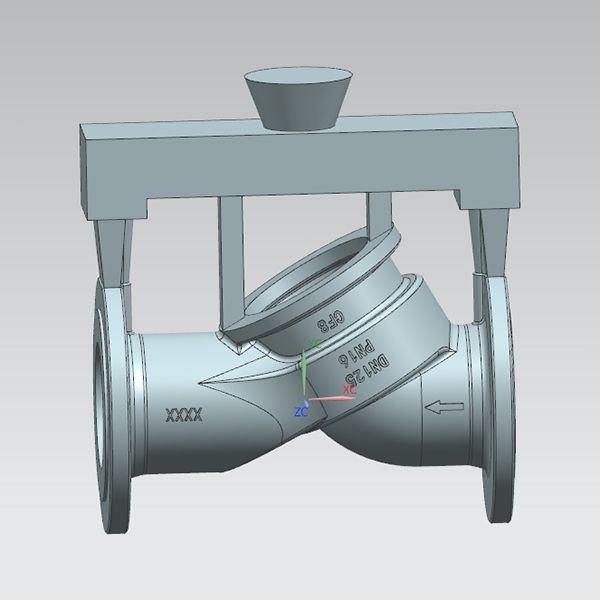

Our company has a strong and professional technical team. We use advanced CAD, CAE, CAM and other software designs to continuously improve innovation capabilities and establish a huge standard mold database. Our team of experts has many years of experience in design and development, and we continue to accumulate to provide customers with better quality molds and strong technical support.

Maybe you are just an idea or concept, you can start working with us so that we can put your idea into a 3D model or sample. The headquarter team makes full use of the best knowledge and skills to communicate closely with customers to design high-quality molds. However, if you give us a complete CAD drawing or 3D model, first we will review the analysis, design, manufacturing, production without any problems, we will follow every step closely.

We have CAD / CAM / CAE system, mainly using the following advanced software for design and engineering:

- Pro / Engineer / SolidWorks / Unigraphics (3D modeling)

- Auto CAD (2D modeling)

- CATIA (3D modeling)

- MasterCAM (CNC programming)

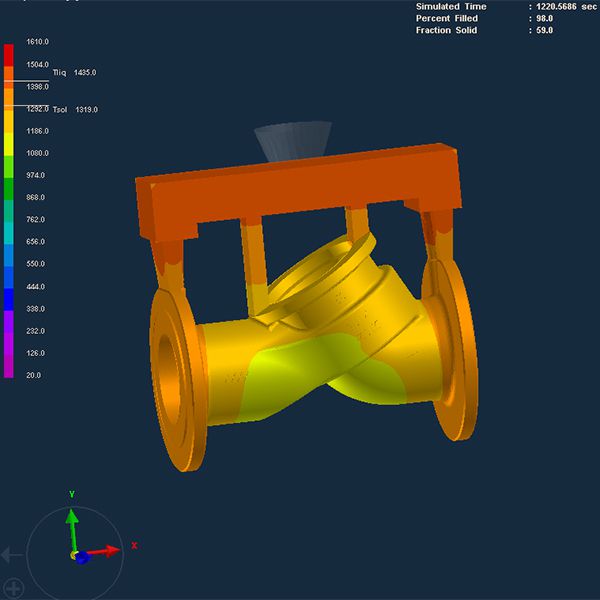

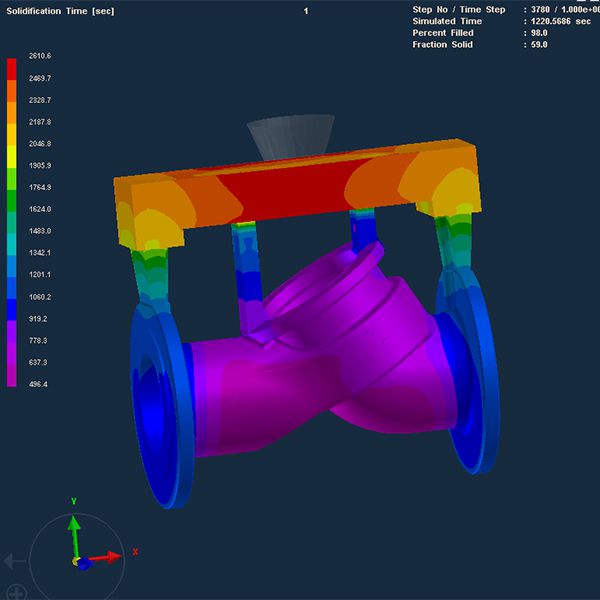

- Mold flow analysis (injection simulation/deformation simulation)

Mold design is the most important step in mold manufacturing. In order to ensure high-quality plastic parts, we analyze and determine the mold structure from the gate, runner, cooling system and ejection system to ensure the best solution. At the same time, we also pay more attention to details, such as the selection of mold steel, mold base, mold accessories, and plastic raw materials. Before starting production, we will send the mold design and drawings to the customer for approval. The headquarters communicates on the basis of standardizing employee behavior, and clearly requires employees to ensure that the quality of products and services requires frank, simple and effective communication with customers, and seeks team members to suggest organizations to improve work efficiency.

-

- Material Selection Nickel-based alloys are renowned for their oxidation and corrosion resistance in harsh environments and high-temperature applications. Learn More

-

- Manufacturing KRT, established in 2003, is a national high-tech enterprise with 20 years of industry experience, integrating design, production, sales, and service. Learn More