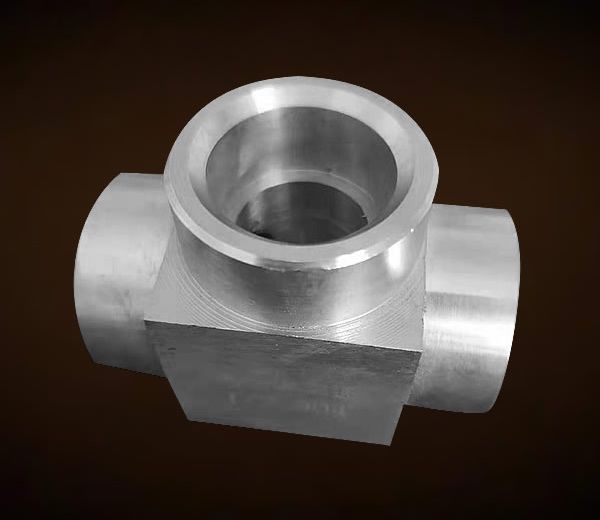

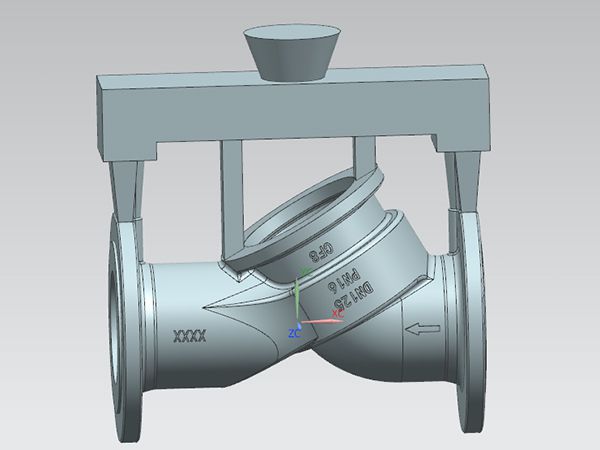

Stainless steel investment casting is a type of lost-wax casting process that involves solidifying stainless steel by pouring it into molds to obtain solid stainless steel components in the desired shapes. When both steel performance and corrosion resistance are required, stainless steel investment casting can be considered, making stainless steel a widely used material in casting production. Stainless steel castings are extensively used in various fields, including food and beverage, chemical and pharmaceutical industries, medical device manufacturing, construction, household appliances, shipbuilding, automotive manufacturing, energy and industrial sectors, pumps, and valves.

Here are some commonly used types of stainless steel materials:

- Stainless Steel 304 (CF8)

- Stainless Steel 304L (CF3)

- Stainless Steel 316 (CF8M)

- Stainless Steel 316L (CF3M)

- Stainless Steel PH17-4

- Stainless Steel 2205

- Stainless Steel 2507

If you do not see the stainless steel material you are looking for, please feel free to contact us, and we will help you find the suitable material.

Nickel-based alloys are renowned for their oxidation and corrosion resistance in harsh environments and high-temperature applications.

Hastelloy alloys are common casting materials with high corrosion resistance. The inclusion of molybdenum makes Hastelloy alloys harder, stronger at high temperatures, and very useful in welding applications. These nickel-based alloy castings are easy to manufacture and shape, possessing good ductility for forging and cold working.

Here are some of the most commonly used nickel-based alloys:

- K418

- K418B

- Inconel 713c

- Inconel 713LC

- Hastelloy C276

- German Industrial Standard/European Standard 2.4819

If you do not find the nickel-based alloy material you are looking for, please do not hesitate to contact us, and we will assist you in finding the appropriate material.

Carbon steel is a highly popular material for steel castings due to its low material cost and a variety of material grades. Carbon steel castings are commonly used and can be heat-treated to enhance their strength, ductility, and other properties, making them widely applicable across various industries.

Carbon steel is known for its durability, structural integrity, and is one of the most widely used alloys worldwide.

Carbon steel can be classified into the following types based on carbon content:

- Low Carbon Steel (C < 0.20% C): High surface hardness, wear resistance, and good ductility.

- Medium Carbon Steel (C content 0.20% to 0.50%): More durable, more flexible, stronger, with good ductility and impact resistance, easy to process in annealed conditions.

- High Carbon Steel (C > 0.50% C): High strength, good shape memory, and wear resistance.

-

- Manufacturing KRT, established in 2003, is a national high-tech enterprise with 20 years of industry experience, integrating design, production, sales, and service. Learn More

-

- Mold Design We use advanced CAD, CAE, CAM and other software designs to continuously improve innovation capabilities and establish a huge standard mold database. Learn More