KRT, established in 2003, is a national high-tech enterprise with 20 years of industry experience, integrating design, production, sales, and service. Our company boasts a professional technical team and is equipped with state-of-the-art facilities, including shell rooms, wax rooms, and machine shops. We are here to assist you in overcoming various challenges in stainless steel casting and machining.

-

Shell room

Shell room

-

Wax room

Wax room

-

140 Ton C-Frame Wax Injector

140 Ton C-Frame Wax Injector -

240 Ton C-Frame Wax Injector

240 Ton C-Frame Wax Injector -

30 Ton Hydraulic Press

30 Ton Hydraulic Press -

16 Ton Automatic Wax Injection Machine

16 Ton Automatic Wax Injection Machine

Mold Making

Mold Making Wax Injection

Wax Injection Wax Assembly

Wax Assembly Shell Making

Shell Making Dewaxing

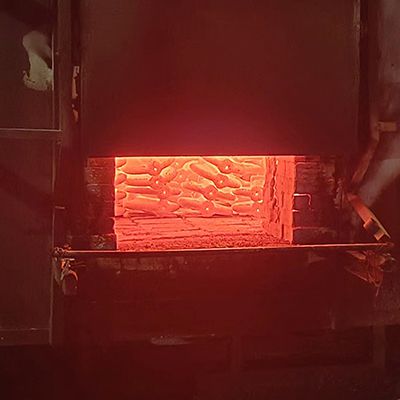

Dewaxing

Setting

Setting Firing

Firing Casting

Casting Shot Blasting

Shot Blasting Cut Off & Grinding

Cut Off & Grinding

The advanced testing equipment includes optical spectrometers, metallographic microscopes, hardness tester, universal material testing machine, and coordinate measuring machine (CMM). Our quality control processes adhere to various international standards such as GB, ASTM, ASNI, BS, DIN, JIS, etc., producing precision castings and machined components using stainless steel, carbon steel, alloy steel, etc.

-

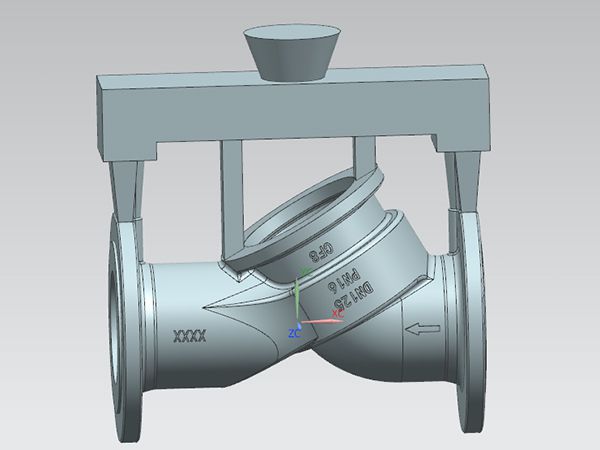

- Mold Design We use advanced CAD, CAE, CAM and other software designs to continuously improve innovation capabilities and establish a huge standard mold database. Learn More

-

- Material Selection Nickel-based alloys are renowned for their oxidation and corrosion resistance in harsh environments and high-temperature applications. Learn More